Description

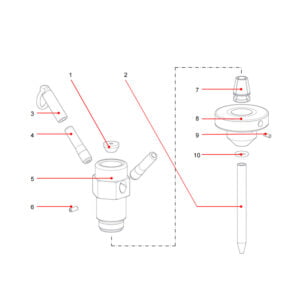

Waterjet cutting parts waterjet plunger

Win-Win provide all brands of waterjet cutting parts, suitable for cutting head and the intensifier pump.

FAQ of the waterjet cutting machine and waterjet cutting parts:

Professional waterjet cutting maintenance manual

Waterjet Repair Guide

1. Routine maintenance measures

1. Check whether the hydraulic system is running normally. If any abnormal sound or abnormality is found, stop the machine immediately for inspection.

2. Regularly clean the high-pressure pump and the high-pressure pump filter, shell and filter screen, especially when changing oil, overhauling and replacing parts.

3. Regularly inspect motor cables and wiring to ensure they are dry, clean and protected.

4. Regularly check the pressure gauge and flowmeter to ensure accurate measurement and clear display.

5. Regularly check whether the nozzle is clogged or worn, and if any problem is found, it should be replaced in time.

2. Maintenance Manual

1. The installation of the machine should be firm, and there should be no collisions, tilts, etc. There are standard requirements for the installation of the machine, and the relevant regulations of the manufacturer must be followed.

2. During the use of the machine, refueling, oil change and cleaning are required. The electrical box needs to be opened regularly for cleaning, and if the cable is damaged, replace it immediately.

3. Maintenance of the hydraulic system, including checking the cleanliness of the hydraulic oil, the amount of oil, replacing the hydraulic oil and filter elements, etc.

4. Maintenance of bearings, including checking the degree of wear of bearings, replacing worn bearings, oil seals and other parts inside the machine.

5. The circuit maintenance of the machine, including the inspection of parts such as card boards and terminal blocks, the inspection of line connectors, and the replacement of cables.

6. Maintenance of the high pressure pump, including dismantling the high pressure pump, cleaning the pump body, checking the condition of the seals, replacing the seals, etc.

7. Replace the cutting nozzle, including disassembling the cutting nozzle, checking the nozzle hole, replacing with a new cutting nozzle, etc.

8. Operations such as replacing the sand water valve and pressure sensor must be performed in accordance with the manufacturer’s regulations and instructions.

3. Safety precautions

1. When operating the machine, the staff should wear protective equipment throughout the process to ensure their own safety.

2. Excessive water pressure will cause fatal damage to the human body, so it is necessary to pay attention to the output direction of the high-pressure water flow to avoid hurting people.

3. When maintaining the machine, the power supply should be cut off first to ensure the safety of the operator.

4. Machine maintenance needs to be equipped with corresponding tools and equipment, and relevant operating steps should be followed to avoid unnecessary accidents and losses.

In short, the repair and maintenance of the machine is the key link to ensure the normal operation of the machine and prolong the life of the machine. Only scientific and reasonable repair and maintenance can effectively help machines and equipment to show better performance and effect during long-term use.

If you need any maintenance advice regarding the waterjet cutting machine or need waterjet cutting parts, please contact us!