Description

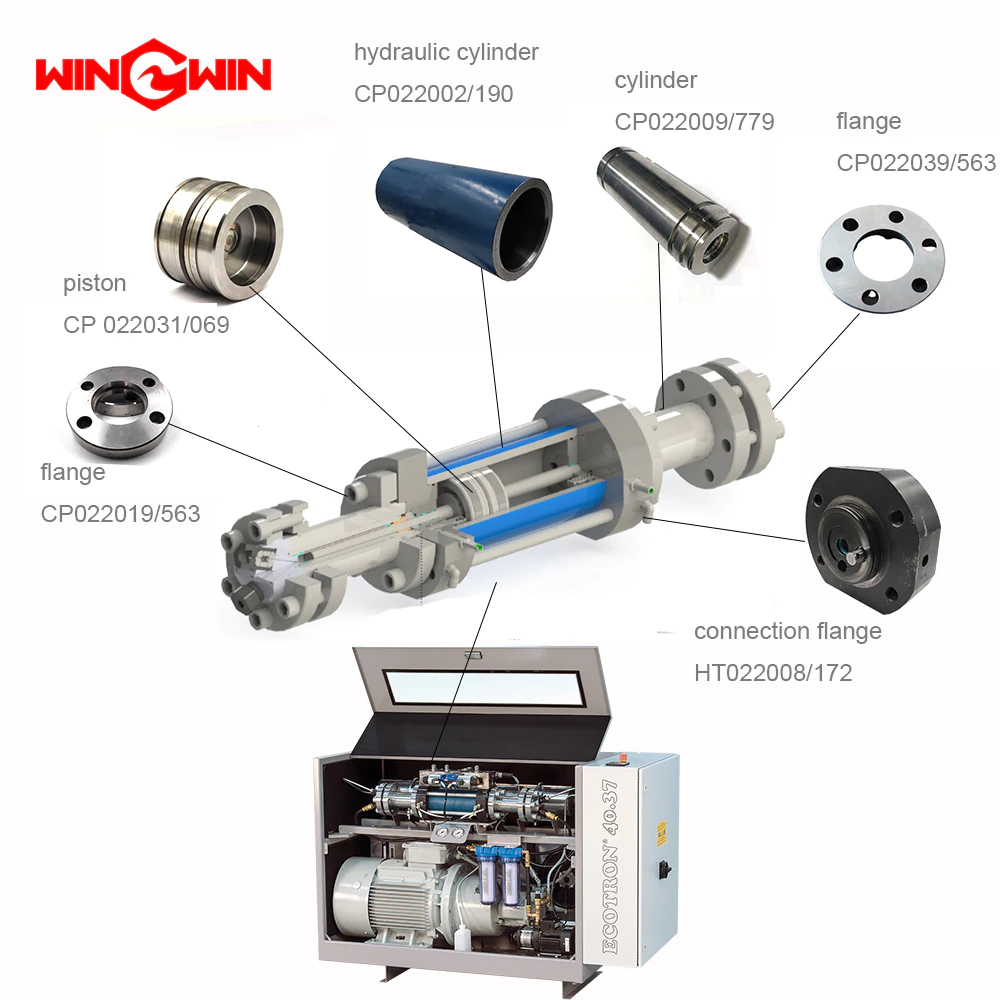

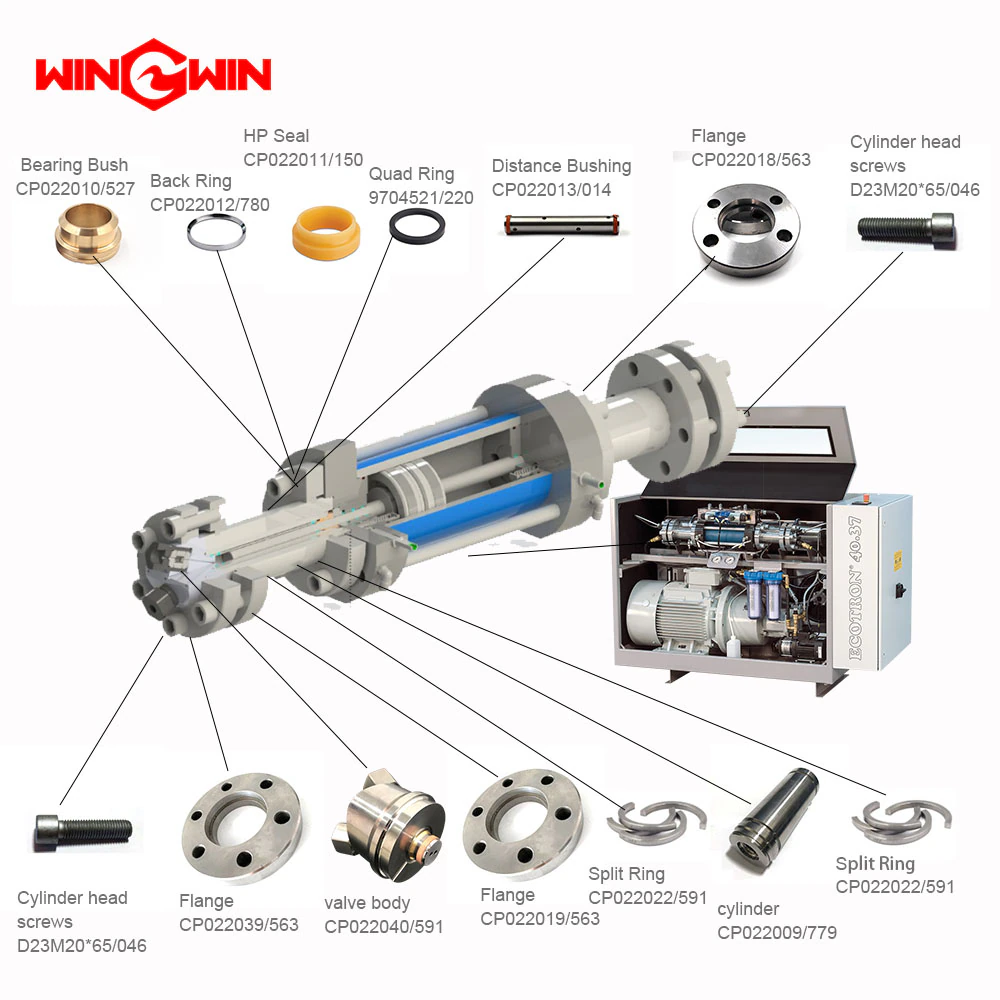

Waterjet Intensifier Parts HT022008/172 Connection Flange Waterjet Cutting Spare Parts for Waterjet Cutting Machine

FAQ for Waterjet Cutting Machine and Waterjet Intensifier Parts:

After the holiday, water jet cutting machine start-up precautions

How do secular stagnant waterjet pumps start after the holidays?

In cold winter, in areas with low temperature, the following points need to be paid attention to when starting up a machine that has been stagnant for a long time:

1. Check whether the low-pressure water meter reaches 0.5MPA, if not, it means that the low-pressure water is blocked or there is a high probability of freezing

2. Check the hydraulic oil, observe whether the state of the hydraulic oil is qualified, do not appear the phenomenon of milky white oil (there is water in the oil), and must be replaced or dealt with if there is an abnormal state

3. Check whether the waterway is normal, test the waterway by manually adjusting the water pump, and observe whether the water filter element or valve body on the waterway is frozen

4. Check whether there is icing on the high-end end, pay attention to on/off valve repair kit and Waterjet Intensifier Parts check valve repair kit

5. Remove the orifice and nozzle, this kind of wearing parts, remember not to start the machine directly without confirming the state of the machine, it will cause unnecessary losses

6. The moving lead screw of the Waterjet cutting table needs to be oiled. If it is an automatic lubrication system, it also needs to be lubricated by jogging for a stroke before it can be used normally.

7. Reduce the speed of the machine tool and manually run the machine tool several times

8. Press the waterjet pump to orifice, turn on the low-pressure mode of the oil pump and run it for ten minutes, there is no problem at about 100MPa and it can work normally

Waterjet Intensifier Parts HP seal, oil seal, filter, orifice are basically replaced directly when starting up