Description

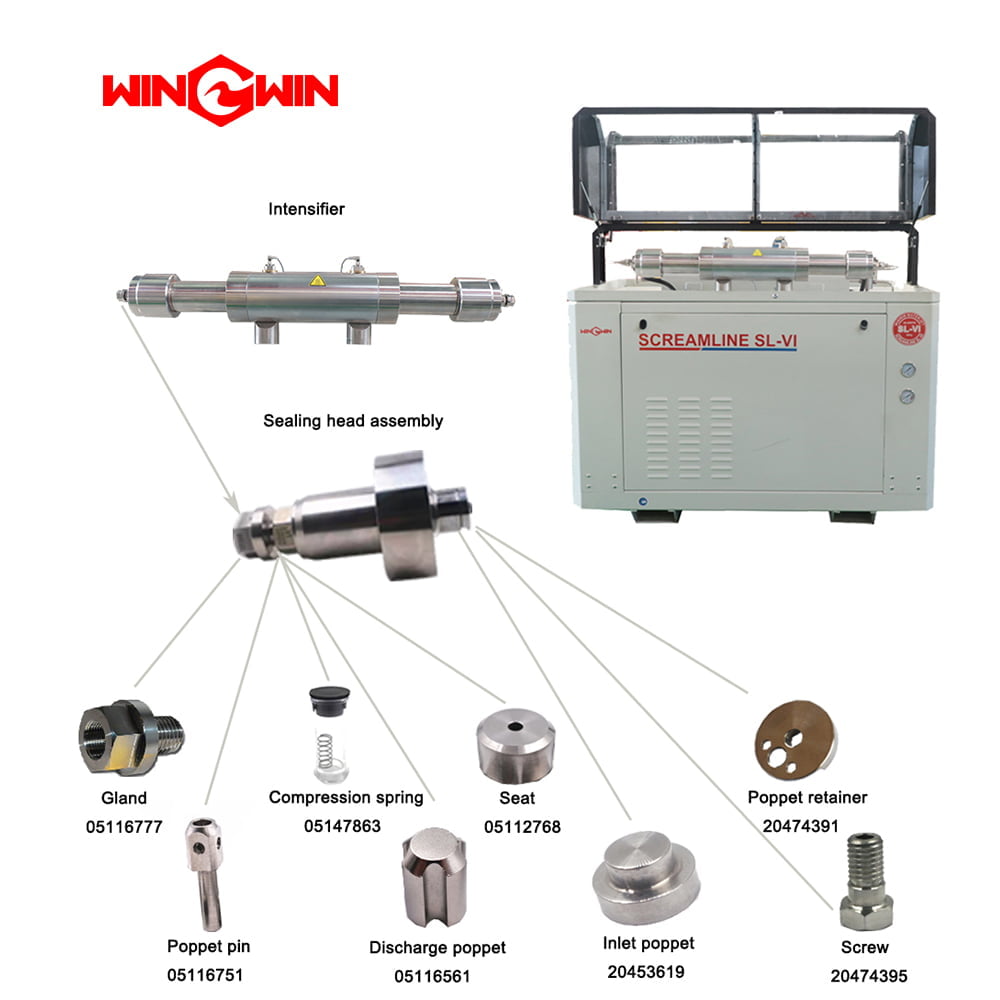

Waterjet cutting parts 05130091 hydraulic seal cartridge assembly

Waterjet cutting parts 05130091 installation: the hydraulic seal is installed in the hydraulic cylinder head, normally there will be two sets of the hydraulic cartridge seal assemblies on the intensifier pump

The water jet oil seal function refers to a sealing device using high-pressure water jet cutting technology, which can prevent lubricating oil and external dust, impurities, etc. from entering the machine, and ensure the normal operation of the water jet. The sealing principle of the water jet oil seal is to use the oil film between the oil seal lip and the shaft to form a hydrodynamic pressure balance to prevent the leakage of the working medium. The material of the water jet oil seal is generally various rubbers, such as nitrile rubber, fluorine rubber, silicone rubber, etc., which have the characteristics of softness, elasticity and good oil resistance