Description

waterjet supplier have the advantage that they can integrate equipment, which is conducive to installation and commissioning. the advantage of R & D design, which make our own new products more advantageous. they are for high-end water cutting customers to do services, many water cutting factories around the world, have their own unique characteristics, so choosing a suitable waterjet supplier for customers are very important.

- target for service: customers according to their own equipment positioning, 87k water cutting equipment needs a more professional team for maintenance, we needs to have better service, 87k waterjet machine more for cutting more than 200mm metal, the pressure reached by the equipment is very high, which is a great test for the sealing and parts of the equipment.

- target for quality: every country on the price positioning is totally different, which has to mention the issue of tariffs, freight and the value of the product itself. What we mentioned above can cause a higher price. Therefore,spare parts this time to be purchased are not cost-effective.

- Waterjet supplier’s after-sales strengths: we will pay a visit to the customer sites, which are better service conditions, while Waterjet supplier has the ability to solve the problems remotely, English or local language communication is more dominant.

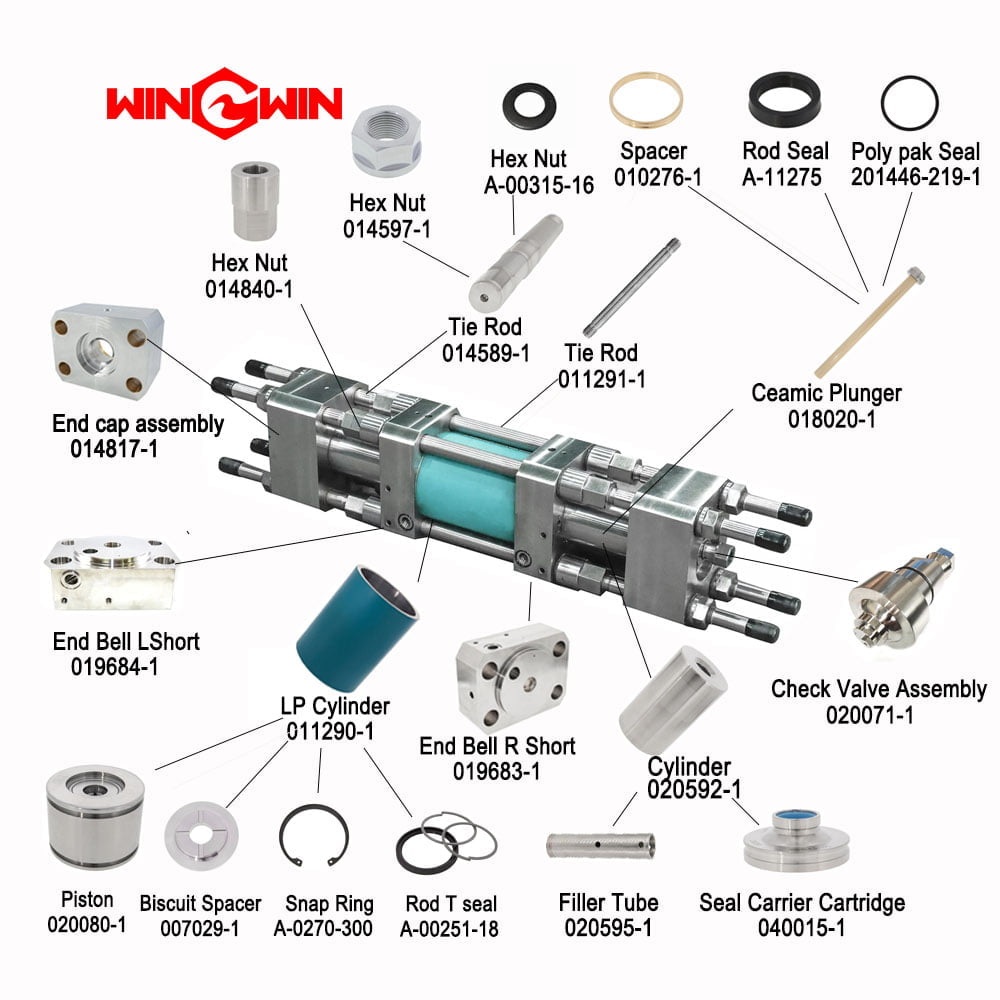

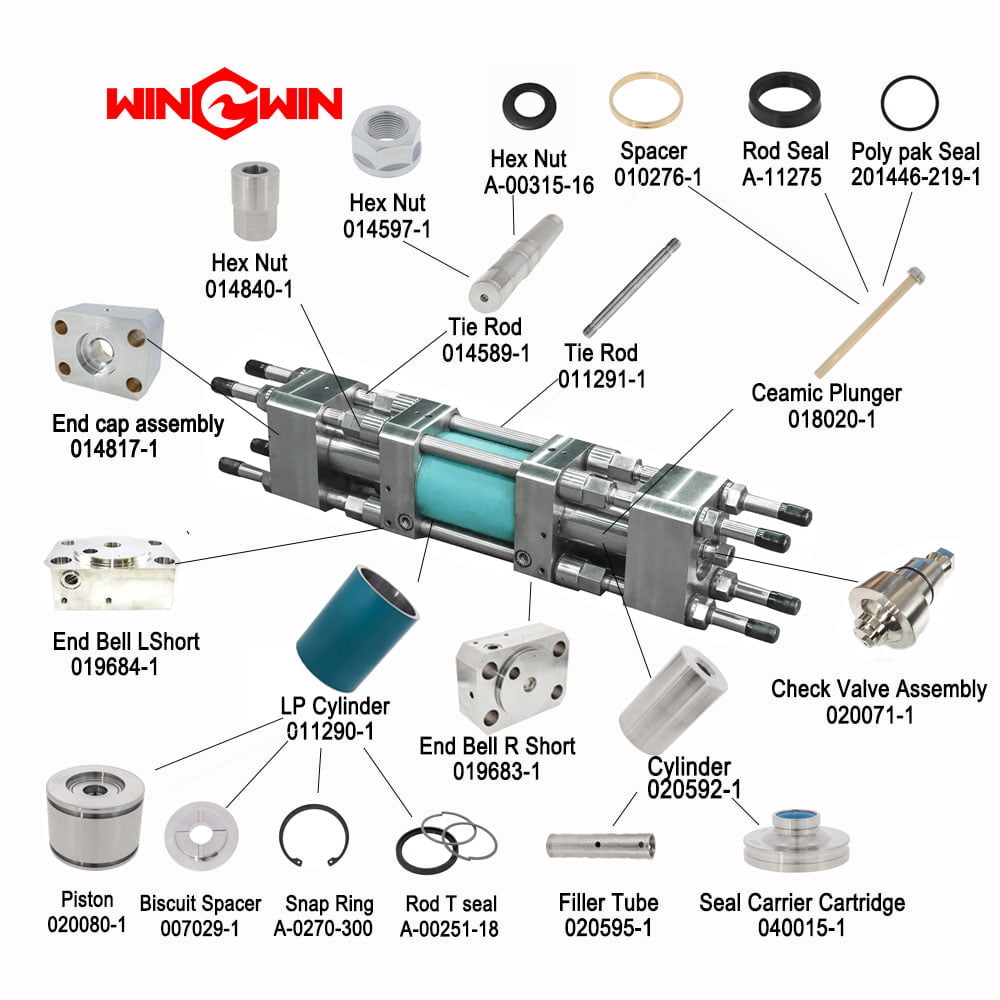

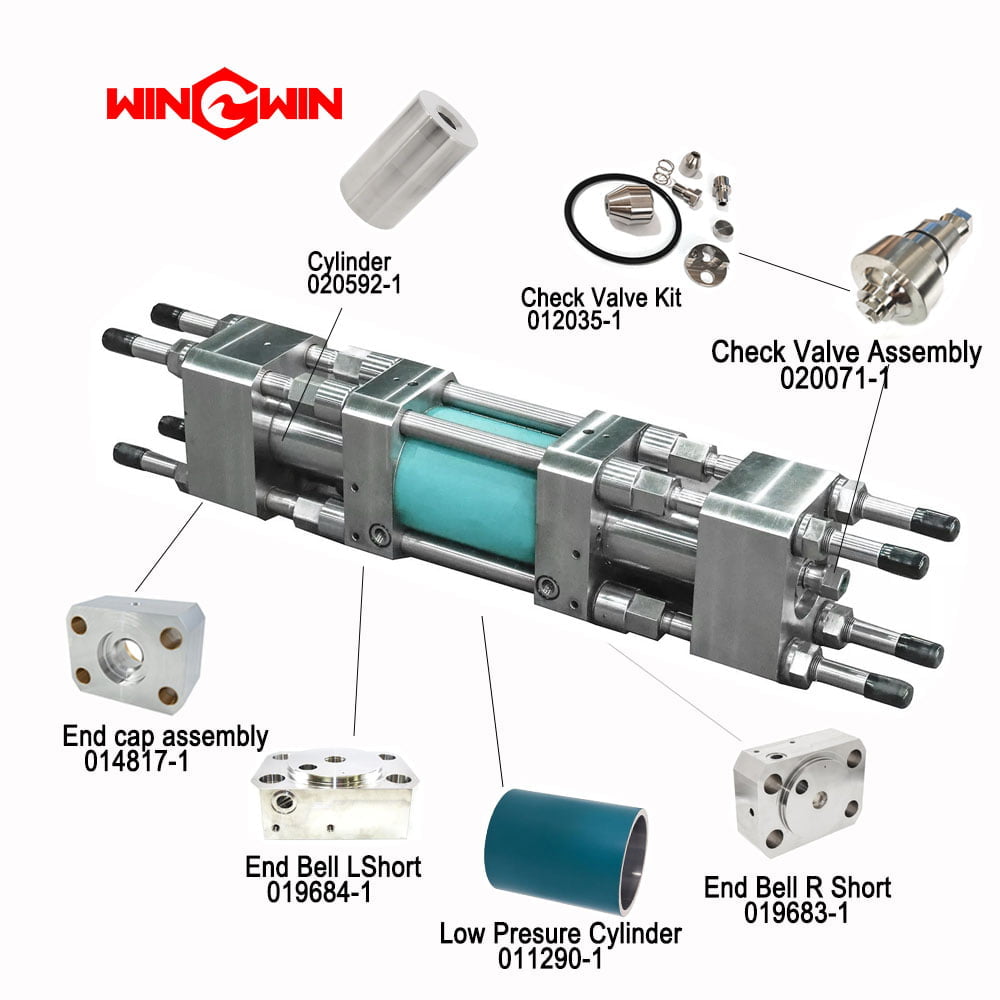

- The price provided by waterjet supplier,the price of water cutting accessories sometimes fluctuated significantly, which is related to several factors, waterjet supplier’s local material costs, labor costs, site costs, etc., on the other hand, the gap in technology also has some effects. The appearance of water cutting accessories looks like stainless steel, but ARE not ordinary stainless steel on the market. After the raw materials are purchased, they need to go through heat treatment, oil immersion, stress relief, pressure testing and other processes, and finally processed by lathe, which can be said to be very complicated. It is difficult for customers to tell their differences, because many Waterjet supplier will buy stainless steel materials on the market for direct processing, which can cause many dangerous accidents, Like causing motor parameter losses.

Waterjet supplier is supposed to do the following five things:

- After-sales feedback speed: in the face of the problem of time difference, waterjet supplier should do 24-hour service, although this is not humanized, a qualified waterjet supplier should should be on duty and give the customer’s problem more primary priorities.

- Delivery time: as a qualified waterjet supplier, for the commonly used water cutting accessories should be in stock, which can reach 1-2 days, even have local inventory. Many customers can get parts and install them on the equipment on the same day or the next day, which can greatly reduce the loss caused by the customer’s equipment shutdown.

- Professional business personnel: customers generally with waterjet company sales staffs get in touch. Therefore, the business personnel must have received professional training in water cutting products. Some conventional problems can directly communicated with customers to solve. It is necessary and desirable to action in this way.

- waterjet machine company establishment time: stability is not strong, it is recommended that customers should choose the historical waterjet company, especially more than ten years, One reason is a lot of experiences they gained, the other reason is such companies will not fail because they put their reputation in the first place.