Description

Waterjet spare parts 712101-1 Hyplex Minor Repair Kit OEM

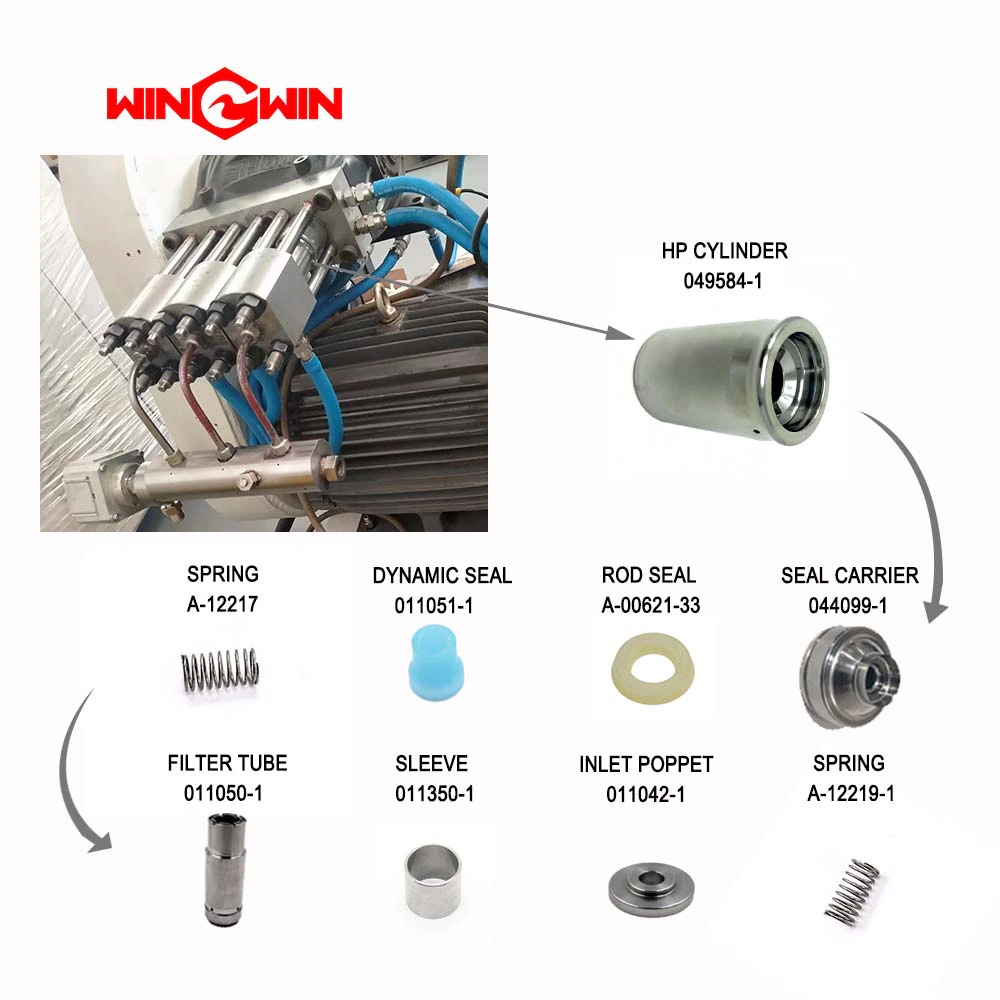

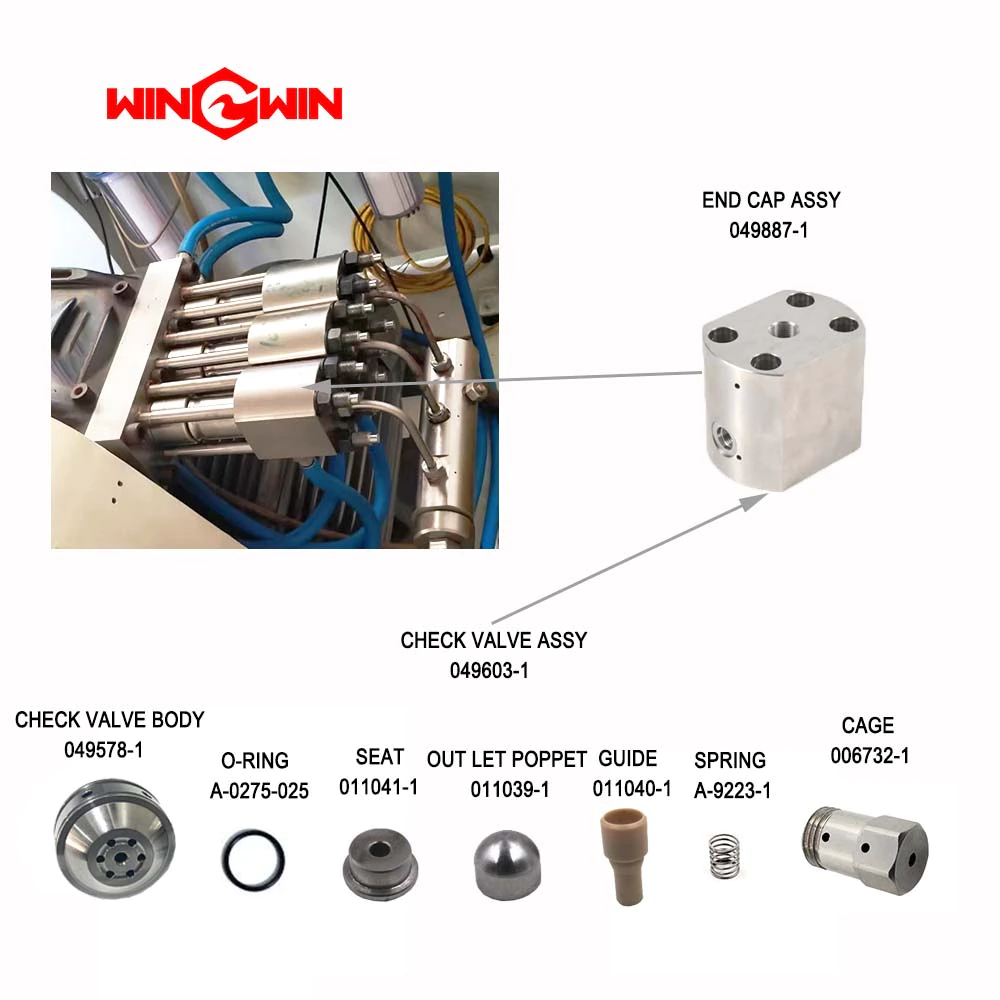

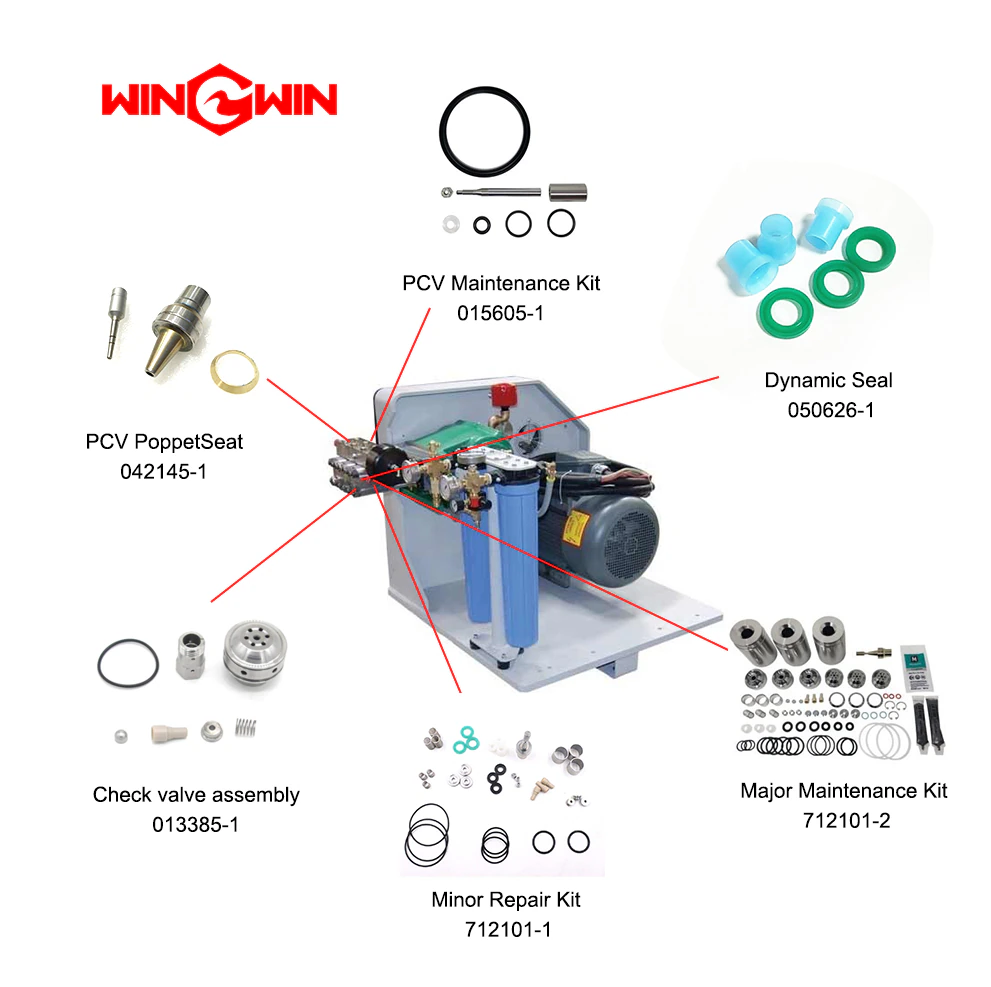

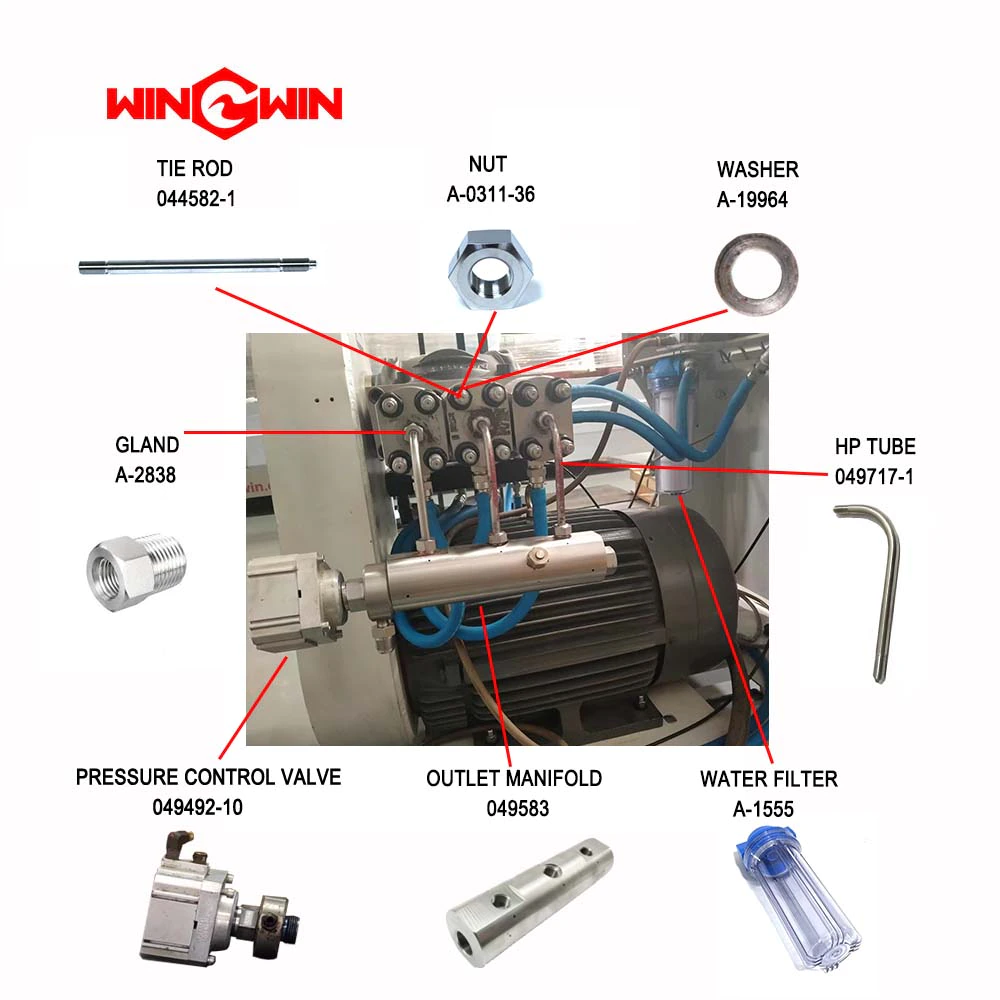

| Name | Qty | Description |

| 011051-1 | 3 | SEAL;DYNAMIC;EAGLE;5/16 ID;HDS WHITE |

| A-00621-33 | 3 | SEAL;ROD;NA;DISOGRIN;7/16 ID;11/16 INCH OD;1/8 INCH |

| 011042-1 | 3 | POPPET;INLET;CHECK VALVE;EAGLE;STAINLESS STEEL |

| 011040-1 | 3 | GUIDE;NA;OUTLET POPPET;CHECK VALVE;EAGLE;NA |

| 011039-1 | 3 | POPPET;OUTLET;CHECK VALVE;HYPLEX;STAINLESS STEEL |

| 011041-1 | 3 | SEAT;OUTLET;POPPET;EAGLE;STAINLESS STEEL |

| 042145-1 | 1 | POPPET/SEAT ASSEMBLY;PRESSURE CONTROL VALVE;HYPLEX HYBRID |

| A-0275-033 | 3 | O-RING;BUNA-N;70 (SHORE A);-033 |

| A-0275-025 | 3 | O-RING;BUNA-N;70 (SHORE A);-025 |

| A-1903 | 1 | EMERY PAPER;320 GRIT;WITH ADHESIVE BACK |

| A-4689 | 1 | GREASE;FOOD GRADE;1/4 OUNCE TUBE |

| SB-0168 | 1 | SB;INSTALLING HYPLEX MINOR MAINT. KIT |

| A-9223 | 3 | SPRING;COMPRESSION;STAINLESS STEEL;NONE;.27 ID;.322 OD;.40 INCH;4.0 LBS/IN;CLOSED & GROUND |

| A-12219 | 3 | SPRING;COMPRESSION;STAINLESS STEEL;NONE;.352 ID;.42 OD;.81 INCH;3.7 LBS/IN;CLOSED & GROUND |

| 011350-1 | 3 | SLEEVE;NA;FILLER TUBE;EAGLE |

| A-20386-1 | 2 | LUBRICANT;ANTI-SEIZE;NA;5 GRAMS |

| 012306-DWG | 1 | HIGH PRESSURE ASSEMBLY;55 KSI HYPLEX;NA;NA |

| A-00720-31 | 3 | SEAL;ROD;NA;NITRILE;5/16 ID;9/16 OD;1/8 INCH |

| A-0275-119 | 1 | O-RING;BUNA-N;70 (SHORE A);-119 |

| A-0275-120 | 1 | O-RING;BUNA-N;70 (SHORE A);-120 |

Questions and answers about waterjet cutting machines and Waterjet spare parts from waterjet cutting users.

1, What are typical spare parts/ consumables of your machine (cutting head, pump, chiller, cleaner) for example every 100 hours / 500 hours / 1000 hours of cutting with 360mpa using abrasive?

Win-Win’s water jet cutting machine provides you with the life and replacement schedule of the relevant Waterjet spare parts of each equipment. Users can check and replace these Waterjet spare parts according to the service life of each Waterjet spare parts in the table.

For example, the water jet cutting head and the enhanced pump have some wearing parts. The water filtration system only needs to replace the filter element regularly. You can buy this equipment from Win-Win or locally. It is a general-purpose industrial water purifier. The refrigerator is maintenance-free and does not need to replace parts. This refrigerator is specially developed by Win-Win for water jet cutting machines. It is different from ordinary industrial refrigerators. It has a very long-lasting and excellent cooling effect for enhanced pumps. It is a water jet cutting machine. A good partner for jet cutting machines.

In addition, these Waterjet spare parts, Win-Win are all produced by ourselves, so the price is favorable and the quality is good, the stock is sufficient, and there is no need to worry about out of stock and production stoppage.

2, If pump is able to generate 420 mpa working pressure. Can t normal cutting pressure be higher for example 380mpa?

A, 380mpa is available, but parts wear and consumption will accelerate, this is not conductive to the long-term stable use and life of the water jet cutting machine.

B, 320-360mpa is the most cost-effective range after market testing, In this way, the failure rate of the machine is low, and the frequency of parts replacement is less, which saves costs and ensures the efficiency of cutting production.

C, 420mpa is the highest pressure, but it is not recommended for users to use 420mpa for a long time.