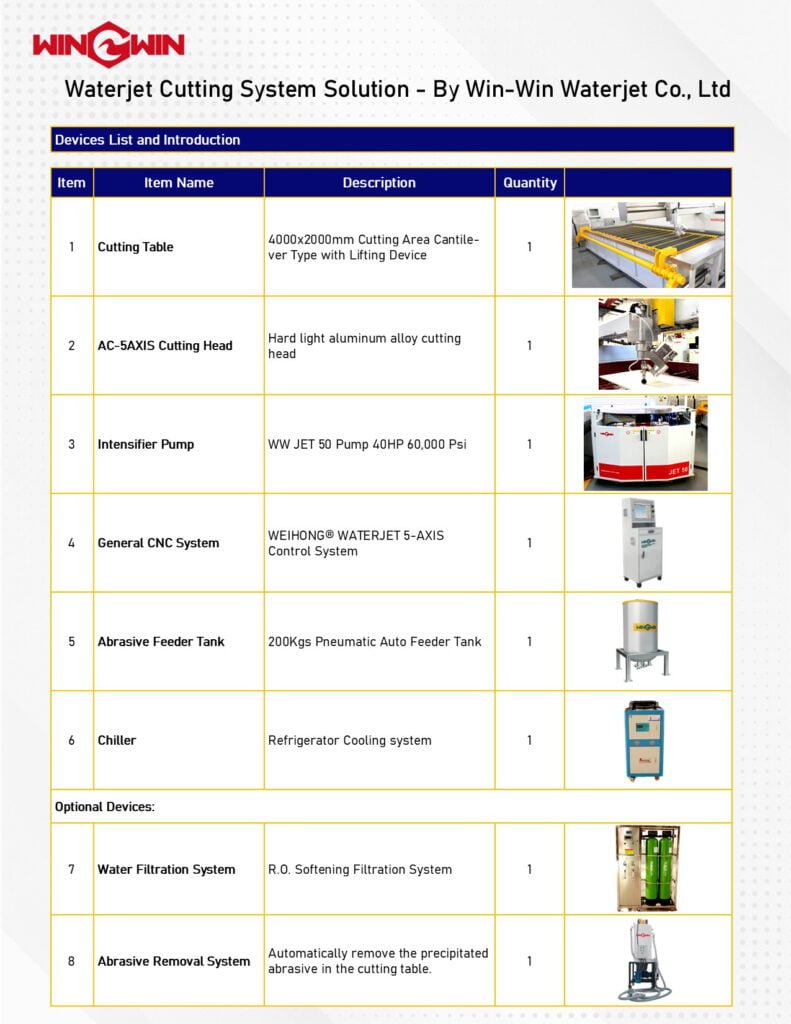

Series | AC-4020 Water Jet | Type | Cantilever Type |

Cutting Angle | 0-±68 Degrees | Control Accurcy | ±0.01mm |

Table Size | 4500mmx2200mmx200mm | Travel Of Z Axis | 200mm |

Cutting Precision | ±0.1mm | RE-Positioning Accuracy | ±0.05mm/m |

Cutting Speed | 11000mm/min | Certificate | CE ISO |

Motor | 30kw / 40HP | After-sales Service | Installation Online Service |

MAX.Cutting Range | 4000mmx2000mmx200mm | Material | Stainless steel |

The configuration of this water jet cutting machine from Win-Win is as follows:

1, 4000*2000mm cutting table

A, The effective cutting area of this cutting platform is 4000*2000mm, and the stroke height of the Z axis is 200mm. Of course, if you want to cut smaller or larger or thicker materials, these can be adjusted according to your actual needs Customized size.

2, AC-5AXIS cutting head

Our AC-5 shaft head adopts a lightweight aluminum alloy shell, which is of good quality, light in weight, beautiful and elegant, durable and has a small operating burden.

3, Cantilever operating cutting table

The cantilever split platform structure can save users a lot of transportation costs, because the equipment with this structure can be loaded and transported in a 20-foot container. If you choose a gantry-style 4000*2000mm platform, you need to use a 40-foot container. Loading and transporting may increase transport costs by 50-100%.

Some users may worry whether the cutting stability and accuracy of the cantilever is worse than that of the gantry? Here I can confidently tell you that there is absolutely no need to worry about this problem with the cantilever produced by Win-Win, because we use super strong and super thick materials to make the cantilever, so as to ensure that the platform does not tremble or shake when it is running.

4. Lifting system

The side-turning feeding and unloading system is very suitable for glass cutting production, marble and granite cutting production, metal cutting production industry and other material cutting and processing industries with large volume and heavy weight.

We can place the materials to be cut on the lifting On the stage, the machine will automatically load and unload materials for us, which can improve work efficiency, save labor costs and time costs, and ensure the safety of operators.

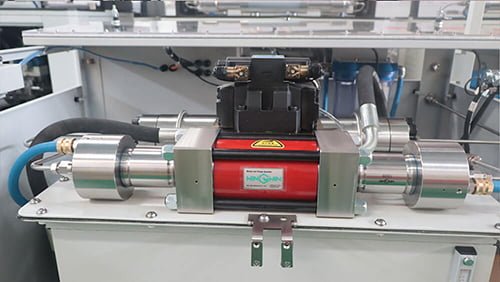

5, JET50 intensifier pump

JET50 intensifier pump is a 60,000psi pump from Win-Win, its flow rate is 3.7L/MIN, its motor rated power is 30kw/40HP, we know that some suppliers match the motor with 37kw/50HP, but In fact, Win-Win uses a super high-quality and strong motor. The efficiency of a 30kw motor can achieve the same effect and pressure as a 37kw motor, and it can save more energy and electricity.

And we can see that the appearance of this intensifier pump is very small and beautiful, and the upper cover is transparent and visible, which is a very classic intensifier pump image.

The supercharger adopts the international standard, easy to operate, and the parts are highly versatile, so there will be no worries about difficulty in purchasing parts or stopping the factory.

Nominal Power Rate | 40HP (30 kW) |

Max. pressure | 420Mpa /4200bar/60,000psi |

Working pressure | 360-380Mpa |

Max. diameter of orifice | 0.33mm |

Max.Flowrate | 3.8L/min |

Accumulator capacity | 1L |

Size | 1600mm*1200mm*1100mm |

Weight | 0.9t |

6, Chiller

As you know, the pump is driven by hydraulic oil for intensifier work. Excessive hydraulic oil temperature will seriously affect the service life of the metal parts and sealing parts of the hydraulic part in the intensifier pump.

Refrigerator Cooling with super cooling effect, internal closed circulation system, more environmental health, beautiful appearance, reliable performance.

7, Abrasive removal system

After the waterjet has been used for a long time, waste abrasive will accumulate in the water sink. When it reaches a certain level, we need to do the work of cleaning the waste abrasive, in the traditional abrasive removal, we have to stop the work of the cutting table and do manual abrasive removal.

Now, with the mobile abrasive removal system, we can remove abrasive without affecting normal cutting, and it is an automatic abrasive removal system.

· Can effectively and quickly remove abrasive in large sinks

· When the waterjet cutting machine operates, the large-scale abrasive removal system operates automatically without affecting each other.

· Simple, economical and effective abrasive removal method, no need to stop the waterjet cutting machine.

·The device can be installed within 10m of the waterjet cutting machine.

· 8 HP diaphragm pump provides powerful suction.

· The flow rate can reach 162L/min.

· Get the ability to clean large sinks with limited floor space.

· The abrasive removal rate is more than 90%.

· During the entire abrasive removal process, the filtered water continues to be discharged into the water sink, and the water sink does not need to be replenished after abrasive removal.

Comprehensive cost savings of more than $8000.00 per year!