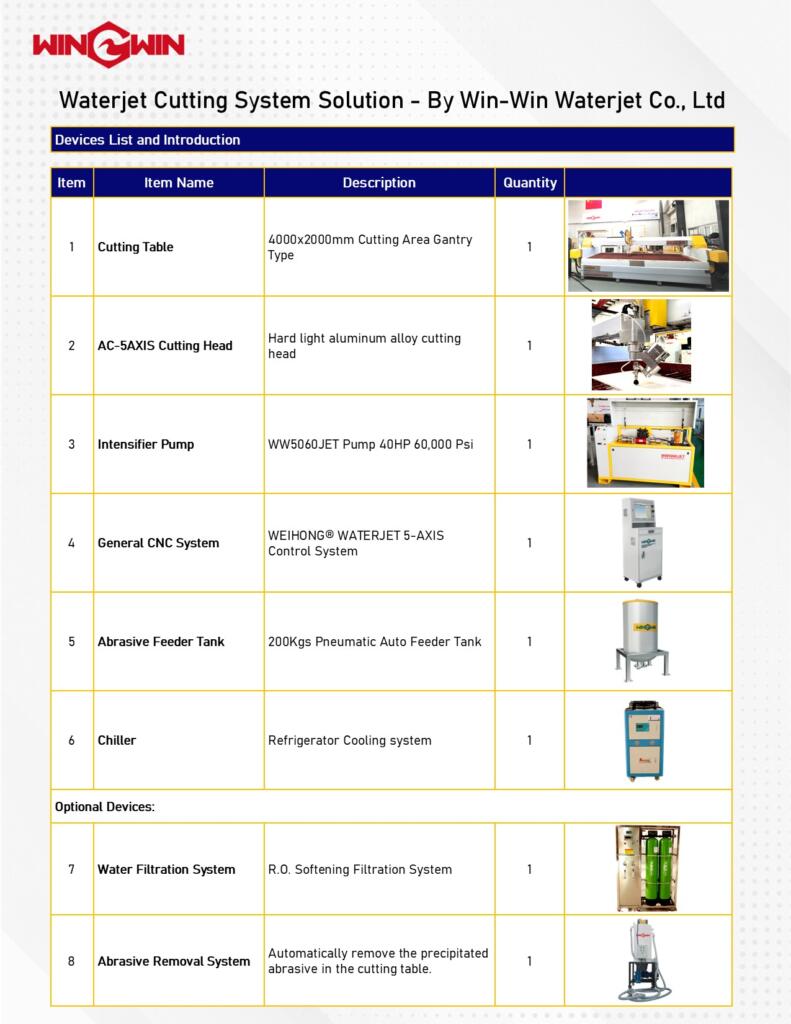

| Series | AC 4020 Waterjet Machine | Type | Gantry |

| Cutting head | AC 5 axis | Control accuracy | ±0.01mm |

| Cutting angle | 0-±68° | Travel of Z axis | 200mm |

| Cutting precision | ±0.1mm | Repositioning accuracy | ±0.05mm |

| Cutting speed | 11000mm/min | Motor | 30kw/ 40HP |

| Max. cutting range | 4000mmx2000mmx200mm | Certificate | CE/ISO |

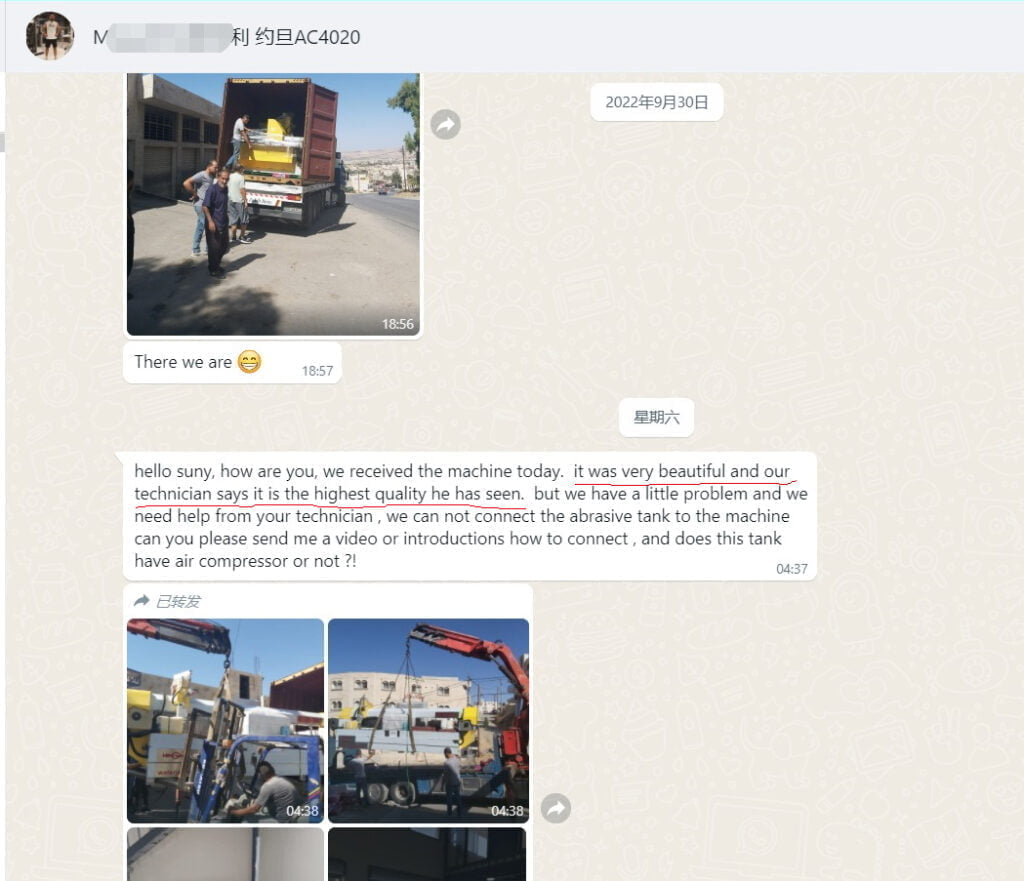

Customer Praise for Our Machine

4020 Gantry Type AC Five-axis Water Jet Cutting Machine

The overall introduction of the equipment:

The gantry structure ensures the stability of the machine tool, and the adjustable structure can ensure the cutting accuracy

The oil immersed structure, the screw slider is permanently soaked in the lubricating oil, which greatly reduces the wear of the screw slider, and the service life is as long as ten years

Cast iron beams and aluminum alloy profiles, stress-relieved structure, high strength, light weight, making the machine tool run easier

Electrical components use Omron and Schneider brands

Provide reliable soft limit for machine tools, safe and secure

Wireless remote control handle, convenient and quick

All stainless steel dustproof design, no rust, no rot

Introduction of AC five-axis features: Maximum swing angle: ±75°

The AC five-axis water jetting machine adds the rotary axis (C axis) and the yaw axis (A axis) of the cutting head on the basis of the original three-direction linear motion, to realize the control of the cutting head, and utilizes the pre-set in the system slope model, through the real-time calculation of the cutting trajectory, and then consider the material and thickness of the workpiece to be corrected, and constantly adjust the angle of the cutting head during the cutting process, so that the cut workpiece can reach a perfect vertical non-slope state. The above functions are particularly important in precision cutting, and the cutting speed and cutting efficiency are improved under the premise of ensuring the cutting accuracy.

At the same time, it can realize large-angle cutting, such as 45° angle cutting, and the AC five-axis waterjet cutting machine can also be used for processing workpieces with a certain slope (such as processing weldment grooves). When the workpiece processed by the user has a slope requirement, the control system can automatically yaw the cutting head at a certain angle around the yaw axis according to the user’s needs, and control the cutting head to rotate around the vertical axis passing the cutting point in real time during the cutting process, to form the slope required by the user.

AC five-axis improves production efficiency, reduces production process, and can improve overall efficiency by 50%-70%

It has lower production cost, directly cuts the required angle, no secondary processing needed

The yaw angle is automatically adjusted through the CNC control system, which is convenient and reliable

The angle between the axis of the rotation axis (C axis) and the axis of the swing axis (A axis) is 90°

A-axis and C-axis transmission adopts harmonic reducer, which has the characteristics of high positioning accuracy and small backlash

Move the air actuator to the Z axis, reducing the swing load of the AC axis

Rotary joints are added on the A-axis and C-axis to avoid the shaking of the cutter head, and at the same time eliminate the cutting error caused by the ellipse of the inner hole of the mixing tube

High-efficiency AC five-axis cutting head for quick part changes and extremely precise tool center point location

WW60JET WATERJET PUMP

Brand | WIN-WIN | Model | WW60JET |

Attenuator capacity | 2L | Driving mode | High performance motor |

Voltage | 380V | Application | Water jet cutting system |

Rated power | 60HP | Maximum water flow | 6.5L/min |

Working pressure | 420Mpa | Continuous working pressure | 320Mpa-380Mpa |

Driving orifices Qty. | 1-4 | Temperature | 5-40°C |

Hydraulic oil type | No.46 anti-wear oil | Cooling method | Cool-heat exchange |

Size (L * w * h) | 1.7m*1.1m*1.4m | Weight | 1.5T |

Intensifier pump features:

Double intensifier linkage mode, longer service life, longer maintenance interval, twice the time of ordinary intensifier pumps

Larger flow rate, can drive nozzle with 0.38mm hole diameter, faster cutting speed

Using 2L large-capacity accumulator, the pressure is stable, which effectively solves the phenomenon of impermeable cutting due to unstable pressure.

Low pressure start, zero pressure wait, high pressure operation, this is a new mode, the device will start at low pressure mode, effectively reduce the motor load, during the cutting process, the machine tool dry running time, intensifier pump high pressure water maintains 60,000psi high pressure, the oil pressure is in a low-pressure state, which is effectively protected and sealed. When cutting is required, high-pressure cutting is enabled. This technology is very suitable for water jet cutting intensifier pumps

double oil filtration system to ensure the quality of hydraulic oil, a box of hydraulic oil can be used for more than five years

Three water filtration systems to ensure water quality and prolong the service life of parts

Using a 60HP motor, the power of the motor has been scientifically calculated, no waste of electricity

Modular frame structure for easy replacement of parts

The top transparent acrylic cover is used, which is beautiful and can always observe the internal situation of the intensifier pump

The control panel has an alarm indicator light. When the external conditions cannot meet the start-up standard, the indicator light will be on regularly, which is convenient for finding the cause and solving it quickly.

Imported high-pressure tubing, shockproof, high pressure resistance, longer service life

The core parts of the intensifier pump are produced in the United States to ensure the quality of the machine tool

The highest pressure can reach 4200bar, with 0.38mm nozzle, it can realize fast cutting and ultra-thick material cutting

The optional mode has two intensifier linkage modes and a single operation mode, and the single operation mode can ensure uninterrupted work